IBERPLATES are composite wear plates consisting of a base plate of low carbon steel and a wear resistant coating applied by arc welding. IBERPLATES are used in the industries facing the most severe wear conditions such as the cement industry, the mining industry, coal fired power plants or the steel industry.

Better homogeneity of the deposit and longer service life

All the composite plates are not the same!

IBERPLATES are produced by using flux-cored wires with a high content of alloying elements. The technology developed by IBERMAROS guarantees a homogeneous structure of the deposit with a high density of vey hard carbides and a perfectly uniform surface. IBERPLATE offer outstanding performance against all types of wear by abrasion and erosion.

Advantages of the IBERPLATE solution

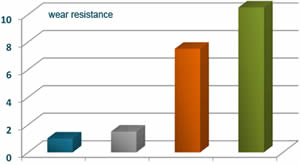

- Higher wear resistance, up to 10 times greater compared to traditional mild steels (ST37 o ST52)

- Longer service life cycles and greater availability of your equipment for production

- Subsequent savings on maintenance costs

Flexibility of supply

IBERPLATES are available in various standard dimensions, thicknesses and coating types. We can also adapt to your special requirements.

- Full size plates for reworking

- Pieces made on specification and ready for assembly

- Complete assemblies and finished parts made in the work shop

- Turnkey projects on site

Easy to use

- Easy to shape and to cut using plasma arc, water jet and laser

- Easy to assembly and to fix with simple methods : stud bolts, inserts, welding, etc.

Comparative wear resistance

(ASTM G-75 test)

IBERPLATE product range IBERPLATE product range

Applications per industry Applications per industry

|

|

|

| IBERPLATE - full size plate |

| |

|

| Plate cut to size |

| CORROSION |

| IBERPLATE with special corrosion resistant alloys |

|

Download product data sheets

|